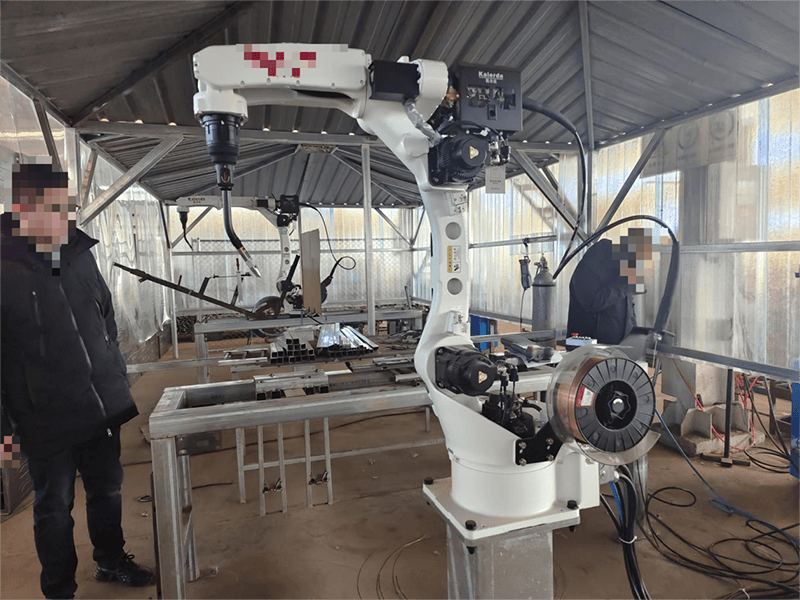

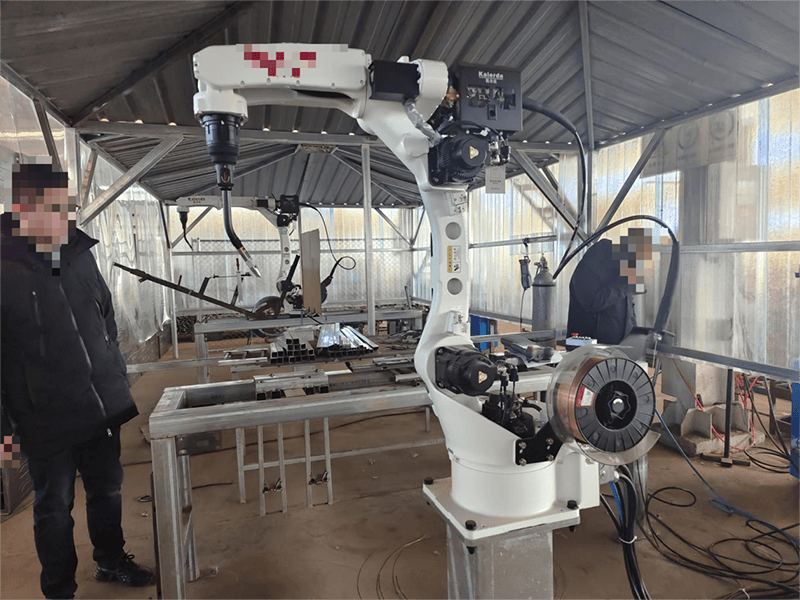

Roboto ea mofuta ona ha e na phoso ea kopano ea workpiece, deformation ea mocheso sebakeng sa phetoho ea ts'ebetso ea welding, hammoho le phetoho ea ntho ea mosebetsi e lokela ho ba le bokhoni, ka hona, ho hlahisa moloko o mocha o na le ts'ebetso e fapaneng ea kutlo, e ka iketsetsa trajectory, tjheseletsa motsotso boikutlo le tjheseletsa paramethara tsa roboto bohlale e tla ba ka sehloohong ntshetsopele tataiso.

Roboto ea mofuta ona ha e na phoso ea kopano ea workpiece, deformation ea mocheso sebakeng sa phetoho ea ts'ebetso ea welding, hammoho le phetoho ea ntho ea mosebetsi e lokela ho ba le bokhoni, ka hona, ho hlahisa moloko o mocha o na le ts'ebetso e fapaneng ea kutlo, e ka iketsetsa trajectory, tjheseletsa motsotso boikutlo le tjheseletsa paramethara tsa roboto bohlale e tla ba ka sehloohong ntshetsopele tataiso.

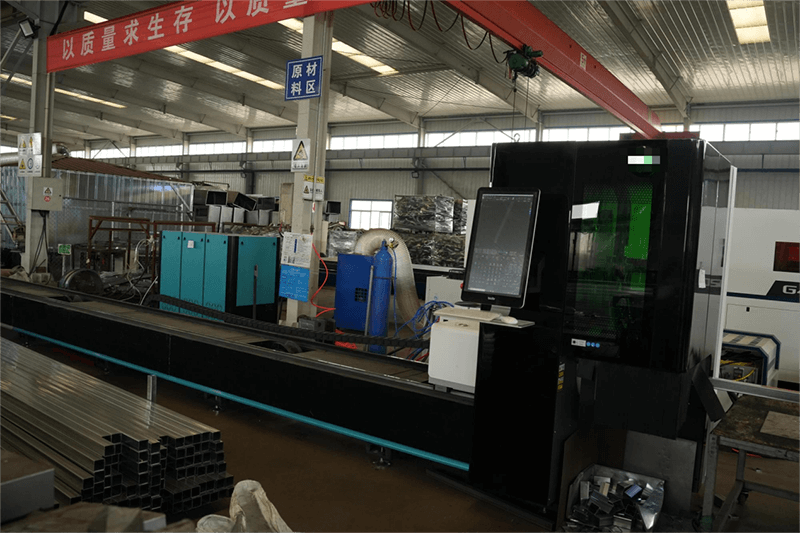

Nts'etsopele ea lisebelisoa tse ncha e tla ntlafatsoa molemong oa ts'ebetso e phahameng, ts'ebetso e phahameng (ho kenyeletsoa ho cheseha hantle) le molemong oa tikoloho.Welding e tla nts'etsapele ts'ebetso e ntle ea welding, e nts'etsapele phepelo ea motlakase e betere le ho nts'etsapele thekenoloji e tsamaellanang ea taolo, ho ntlafatsa tekanyo ea boits'oaro le ho holisa sebaka sa ts'ebeliso ea roboto: fokotsa sekhahla sa sekhechana le sekhahla sa tokiso, fokotsa litšenyehelo tsa ho tjheseletsa, ho ntlafatsa tlhahiso. ho sebetsa hantle (joalo ka: fokotsa, ka mor'a ho futhumatsa pele, mocheso, qoba ho cheselletsa ho chesa, joalo-joalo), felisa khopolo ea "welding ke tšitiso ea mokhoa oa ho etsa tlhahiso".

Nako ea poso: Jun-18-2024